How To Stop Scorch Marks when Heat Printing

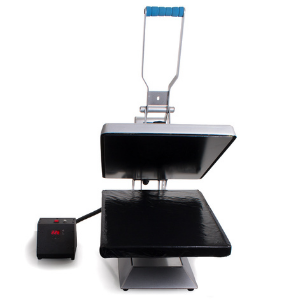

The Tool You Need to Eliminate Scorching

Today’s fabrics are trendy, stretchy, synthetic, and heat sensitive. The Power Platen is designed to add heat to the bottom platen, allowing for a decrease in temperature on the top platen, eliminating the press box and scorch marks on heat-sensitive fabrics like polyester or spandex.

HOW IT WORKS

ELIMINATE SCORCH MARKS

Bottom heat allows for a lower application temperature on the top platen. Sensitive fabrics, like polyester and spandex are exposed to higher heat on the inside of the fabric which eliminates the heat press ox and scorch marks.

DECREASE APPLICATION TIME

Increase productivity with reduced application time. No heat printing pads, pillows, extra cover sheets, or preheating are required, so you get more done in less time, and that translates to your bottom line.

FULLY THREADABLE

Not only is the Hotronix® Power Platen the first on the market to be fully threadable, it also converts any Hotronix® Clam into a fully threadable model when used with a Heat Press Caddie™.